Uncompromising

Quality Standards

Every batch of Natural Support undergoes rigorous testing and quality control measures to ensure safety, purity, and potency meet the highest international standards.

Our Quality Commitment

We maintain the highest standards of quality through comprehensive testing, certified manufacturing processes, and continuous monitoring.

GMP Certification

Manufactured in FDA-certified Good Manufacturing Practice facility

- Good Manufacturing Practice

- FDA recognized worldwide

- Regular audits and inspections

Safety Testing

Comprehensive toxicology and heavy metal testing for every batch

- Yeast, mould, bacteria testing

- Lead, arsenic, mercury, cadmium analysis

- Third-party laboratory verification

Quality Control

Rigorous quality control processes throughout manufacturing

- Dosage integrity verification

- Active ingredient quantification

- Batch-to-batch consistency

Manufacturing Excellence

Our strictly controlled manufacturing process ensures consistent quality and potency in every batch of Natural Support.

1. Raw Material Sourcing

Carefully selected herbs from verified suppliers with quality certificates

2. Extraction Process

Controlled extraction from 1000kg raw material to 500mg concentrated extract

3. Quality Testing

Comprehensive testing for purity, potency, and safety parameters

4. Formulation

Precise blending according to validated formulation specifications

5. Encapsulation

Automated encapsulation with weight and content uniformity verification

6. Final Testing

Complete quality control testing before packaging and release

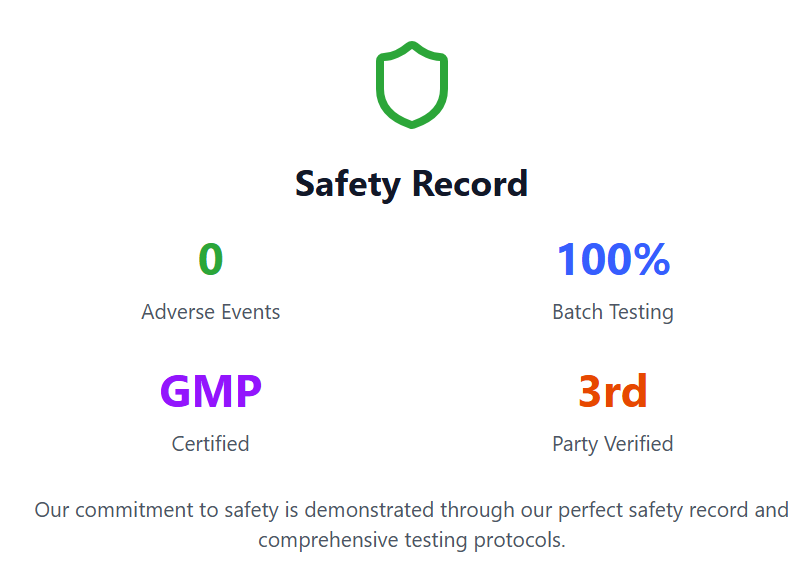

Your Safety is Our Priority

We conduct comprehensive safety testing for every batch to ensure our products meet the highest safety standards and provide peace of mind for our customers.

- Toxicology testing for yeast, mould, and bacteria

- Heavy metal analysis for lead, arsenic, mercury, cadmium

- Third-party laboratory verification

- Allergen control and proper labeling